ERS carries MetaFlo Technologies line of solidification reagents.

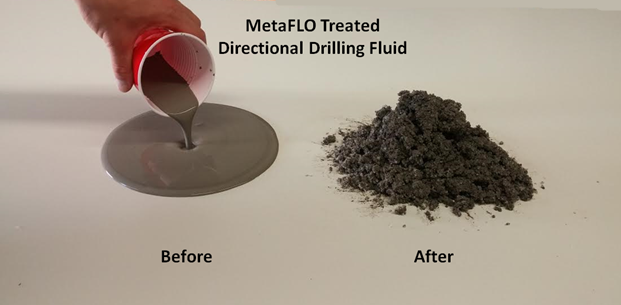

MetaFLO has developed a process that solidifies liquid industrial waste streams in a matter of minutes, watch the videos below. The process includes a patented, high volume mixing unit that facilitates the addition of a powdered formulation of absorptive materials to meet environmental solids criteria and stabilize metals and hydrocarbons. The process can be applied as a mobile waste processing unit or in-situ for high volume continuous batch waste streams.

MetaFlo™ family of Solidification Reagents!

MetaFlo has designed many different reagents for the many different applications, here are a few below.

MetaFlo MF002

Designed to work in conjunction with a LMS mixing unit and is used for the solidification and stabilization of drill fluids. MF002 is designed for use on drill fluid or similar waste that fails the Paint Filter Test PFT and Toxicity Characteristic Leaching Procedure TCLP for Heavy Metals.

MetaFlo MF006

MF006 is a proprietary solidification reagent used with non-pumpable materials and is ideal with MetaFLO mixer equipment delivery system or bucket mixing of semi solids. It has been proven very effective in the solidification of drill cuttings, drilling mud, hydrovac mud and industrial sludge.

MetaFlo MF008

The MF008 reagent, engineered to work in conjunction with MetaFLO’s mixing unit, is ideal for solidifying oil based drill cuttings. MF008 is non-hazardous, non-toxic, chemically inert and consists of naturally occurring minerals. The typical dosages for MF008 is less than 3% w/w .